Ammunition, arms and explosives were manufactured in Vienna not only by specialist armaments companies like G. Roth AG. A number of companies from other sectors converted their production facilities. In spite of the shortage of raw materials, the output remained surprisingly high until 1917. It was only with the dramatic deterioration of the workers’ supply situation that productivity began to drop.

The requirements of war made necessary far-reaching structural changes in the Viennese production sector, culminating in the formation of an armaments complex. A few statistics will give an idea of its economic importance and dimensions. According to a survey conducted by the Ministry of War in November 1916, 1,587 companies in Vienna were working for the Austro-Hungarian army. Apart from transport companies, most were in the armaments and mechanical engineering industries. Estimates made in connection with the food situation of workers in Vienna’s strategic industries put this part of the labour force alone at around half a million.

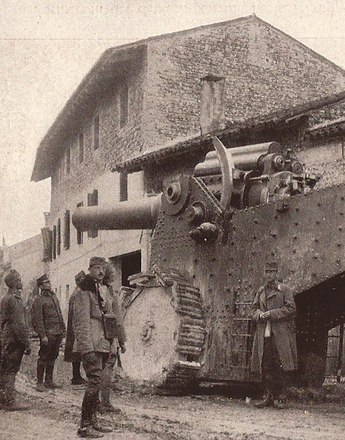

The Austro-Hungarian army entered the First World War with a huge deficit in terms of artillery, shells and the import-dependent and complexly organised production of gunpowder. Considerable efforts were therefore required to increase the output of these production sectors. The armaments industry was affected only to a limited extent at first by a shortage of raw materials. By the end of 1915, however, the dwindling supply of a number of non-ferrous metals was beginning to make itself increasingly felt. In spite of the enormous upsurge in demand, however, it was possible to provide the army with metals at relatively stable prices. In the iron and steel industry, it was not until 1917 that shortages of coal and food caused an increase in price and a supply shortfall. In the last year of the war, inflation and strikes exacerbated the situation.

One of the main Viennese armaments manufacturers was G. Roth AG. It produced ammunition parts at its factory on Rennweg and had a metalworks, a stamping plant and engineering works including a steel mill on Erdberger Lände. It made cartridges, cartridge casings, ignition parts, artillery shells and shell cases, explosives, special machines for making arms and ammunition, and primary materials. A foundry in Simmering and a motor factory in Margareten were acquired during the war. A textile factory in Liesing was transformed into an ammunition factory. At the height of the armaments production the company employed between 14,000 and 15,000 people.

Within the metalworking industry Österreichische Schmidt-Stahlwerke in the 10th district was one of the most important strategic companies. Non-specialist firms also adapted to the changed demand. Österreichische Siemens-Schuckert-Werke (20th and 21st districts), the largest electrical engineering company in the monarchy, made ammunition, as did Hofherr-Schrantz-Clayton-Shuttleworth AG, a company specialising in agricultural machinery. In 1916, forty-seven large Austrian companies, primarily in Vienna and southern Lower Austria, specialised completely or partially in the production of ammunition. Added to them were numerous smaller metalworking companies.

Translation: Nick Somers

Dornik, Wolfram: Verwaltung des Mangels. Die österreichisch (-ungarisch)en Kriegszentralen 1914–1918, in: Schöpfer, Gerald/Stelzl-Marx, Barbara (Hrsg.): Wirtschaft. Macht. Geschichte. Brüche und Kontinuitäten im 20. Jahrhundert. Festschrift Stefan Karner, Graz 2012, 261–274

Mathis, Franz: Big Business in Österreich. Österreichische Großunternehmen in Kurzdarstellungen, Wien 1987

Meißl, Gerhard: Betriebsstättenverteilung in der Rüstungsindustrie des Ersten Weltkrieges. Verteilung von für die Heeresverwaltung tätigen Betrieben des Sekundärsektors mit über 100 Beschäftigten 1916, in: Wiener Stadt- und Landesarchiv/Ludwig Boltzmann Institut für Stadtgeschichtsforschung (Hrsg.): Historischer Atlas von Wien, 5. Lfg., Wien 1994, Karte 2.3.2/8

Stadler, Gerhard A.: Die Rüstungsindustrien der Donaumonarchie und ihre Exporte nach Lateinamerika, 2. Auflage, Wien 1998

Weigl, Andreas: Kriegsindustrie. Die Wiener Wirtschaft im Dienst der Kriegsökonomie, in: Pfoser, Alfred/Weigl, Andreas (Hrsg.): Im Epizentrum des Zusammenbruchs. Wien im Ersten Weltkrieg, Wien 2013, 220–231